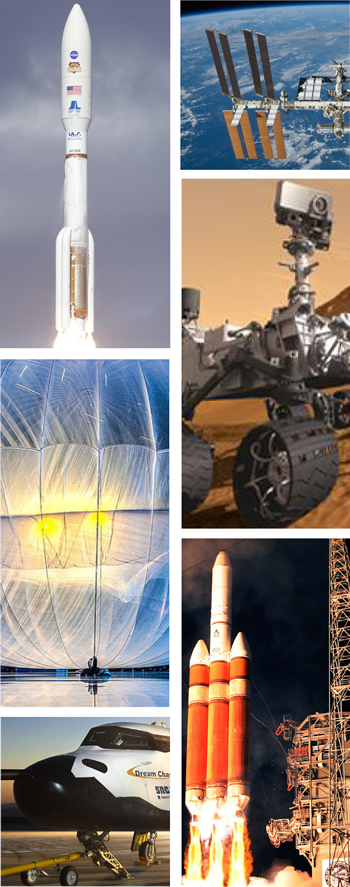

Aerospace

-Tungsten Disulfide (WS2) was designed for NASA as a lubricant that would work in the vacuum of space. WS2 can withstand a wide range of temperatures from absolute zero to 1315°C which makes it ideal for spacecraft and high altitude aircraft. Tungsten Disulfide is impinged to the metal and becomes part of the substrate. Conventional oil lubricant provides a low friction lubricant between two surfaces, where as WS2 makes the two surfaces themselves low friction. Without any liquid tungsten disulfide coated parts are virtually immune to freezing or boiling making WS2 perfect for performing in the rays of the sun and the freezing vacuum.

-While Tungsten Disulfide has been around for over 40 years, Applied Tungstenite was founded in 2012 to provide a fresh look at proven technology. We pride ourselves at looking to the future of WS2 and look forward to working with your engineers to find new applications on state of the art technology.

-Applied Tungstenite also has an efficient passivation line using the environmentally friendly ASM 2700 E method 2 citric acid passivation. Our goal is to speed up the total turn around time on a part by combining passivation and tungsten disulfide into one stop. Give us a call and put our fast estimates and turn around to the test.

Phone: 775-267-1244

WS2 Technical Information

Composition:

A single layer of modified Tungsten Disulfide .5 microns thick

Molecular weight of 248.02

Density of 7.4 gms/cc

Hardness of 30 Rockwell C

Non-magnetic

Uniform silver-gray in color

Substrates:

All ferrous and non-ferrous metals and selective manmade solids and plastics.

However, the harder the substrate, the better the bond.

Adhesion:

High velocity impingement applied at ambient air temperature.

No cure time required

No binders or additional adhesives

Temperatures Range:

-460°F to 1200°F (-273°C to 650°C) in normal atmosphere

-360°F to 2400°F (-188°C to 1316°C) in hard vacuum

Load Capacity/Pressure:

Same as substrate to 100,000 psi

Coefficient of Friction:

Dynamic 0.035 Static 0.07

Coefficients lower then .05 are attainable but will vary with humidity

Chemical Stability:

Inert, non-toxic and non-corrosive

Accepts petrochemical oils and greases, synthetic oils, silicone lubricants and hydraulic fluids.

Does not prevent corrosion of substrate

Lox Compatibility:

Insensitive to detonation by or in the presence of oxygen